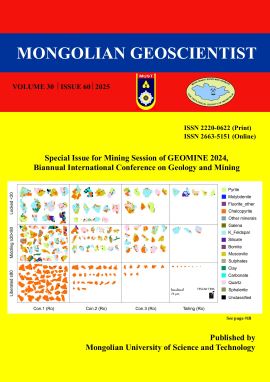

Mineralogical characterization of the flotation products using automated mineral liberation analysis at the Erdenetiin Ovoo Cu-Mo porphyry deposit, Mongolia

DOI:

https://doi.org/10.5564/mgs.v30i60.3584Keywords:

TIMA, phase boundary, associationAbstract

The flotation process is used to extract copper-molybdenum sulfide minerals from ore. The selection of the flotation technology scheme largely depends on factors such as the composition of sulfide ore in the ore body, grain size, and characteristics of the ore mineral association. The chemical and mineralogical analysis of flotation products was collected from the Erdenetiin Ovoo Cu-Mo porphyry deposit. The deposit is the largest porphyry copper-molybdenum deposit in Mongolia. The aim of this study was to demonstrate the occurrence mechanism of copper minerals in flotation tailing using the fully automated Tescan Integrated Mineral Analyzer. The chemical analysis of the flotation products (feed, concentrates and tailings) sample was conducted by X-ray fluorescence, and the mineralogical composition of the flotation feed sample was characterized using X-ray diffraction. The copper content of the flotation tailing was 0.024%. Mineralogical characterization results showed that almost all copper minerals occurred within coarse gangue particles, the primary and secondary copper minerals were accumulated in the size fractions less than 150 μm and 13.5 μm, respectively. The finest grain size distribution was observed in secondary copper particles of size -19 μm. Chalcopyrite was the main copper-bearing mineral, and it was closely associated with K-feldspar and silicate in the flotation tailings. The flotation tailing sample still contained 24.1 wt% liberated primary copper (chalcopyrite) and 24.13 wt% secondary copper due to their extremely fine grain size particle. The mineral map derived from Tescan Integrated Mineral Analyzer analysis revealed that copper minerals mainly occurred as finely disseminated and fully enclosed structures within gangue minerals.

Downloads

614

References

Alcalde, J., Kelm, U., Vergara, D. 2018. Historical assessment of metal recovery potential from old mine tailings: A study case for porphyry copper tailings, Chile. Minerals Engineering, vol. 127, p. 334-338. https://doi.org/10.1016/j.mineng.2018.04.022

Antonijević, M.M., Dimitrijević, M.D., Stevanović, Z.O., Serbula, S.M., Bogdanovic, G.D. 2008. Investigation of the possibility of copper recovery from the flotation tailings by acid leaching. Journal of Hazardous Materials, vol. 158(1), p. 23-34. https://doi.org/10.1016/j.jhazmat.2008.01.063

Berkh, K., Rammlmair, D., Drobe, M., Meima, J. 2019. Case study: Geochemistry and mineralogy of copper mine tailings in Northern Central-Chile. 14th International Congress for Applied Mineralogy, p. 37-40. https://doi.org/10.1007/978-3-030-22974-0_9

Can, N.M., Celik, I.B., Bicak O., Altun, O. 2013. Mass Balance and Quantitative Mineralogy Studies for Circuit Modification. Mineral Processing and Extractive Metallurgy Review, vol. 34(5), p. 348-365. https://doi.org/10.1080/08827508.2012.656779

Celep, O., Yazici, E.Y., Altinkaya, P., Deveci, H. 2019. Characterization of a refractory arsenical silver ore by mineral liberation analysis (MLA) and diagnostic leaching. Hydrometallurgy, vol. 189, 05106. https://doi.org/10.1016/j.hydromet.2019.105106

Chen J., Lan, L., Liao, X. 2013. Depression effect of pseudo glycolythiourea acid in flotation separation of copper-molybdenum. Transactions of Nonferrous Metals Society of China, vol. 23(3), p. 824-831. https://doi.org/10.1016/S1003-6326(13)62535-2

Habashi F. 2010. History of flotation. Mineral Processing and Extractive Metallurgy, vol. 119(4), p. 247-248. https://doi.org/10.1179/037195510X12843862943540

Haberlah, D., Strong, C., Pirrie, D., Rollinson, G.K., Gottlieb, P., Botha, P.P.W.S.K., Butcher, A.R. 2011. Automated petrography applications in quaternary science. Quaternary Australasia, vol. 28(2), p. 3-12. https://aqua.org.au/wp-content/uploads/2013/06/QA_Vol-28_No-2_Dec-2011.pdf

Han, B., Altansukh, B., Haga, K., Stevanović, Z., Jonović, R., Avramović, L., Urosević, D., Takasaki, Y., Masuda, N., Ishiyama, D., Shibayama, A. 2018. Development of copper recovery process from flotation tailings by a combined method of high-pressure leaching-solvent extraction. Journal of Hazardous Materials, vol. 352, p. 192-203. https://doi.org/10.1016/j.jhazmat.2018.03.014

Han, B., Altansukh, B., Haga, K., Takasaki, Y., Shibayama, A. 2017. Leaching and Kinetic Study on Pressure Oxidation of Chalcopyrite in H2SO4 Solution and the Effect of Pyrite on Chalcopyrite Leaching. Journal of Sustainable Metallurgy, vol. 3, p. 528-542. https://doi.org/10.1007/s40831-017-0135-3

Hrstka, T., Gottlieb, P., Skála, R., Breiter, K., Motl D. 2018. Automated mineralogy and petrology-applications of TESCAN Integrated Mineral Analyzer (TIMA). Journal of Geosciences, vol. 63(1), p. 47-63. https://doi.org/10.3190/jgeosci.250

Jefferson, M., Yenial-Arslan, U., Evans, C., Curtis-Morar, C., O'Donnell, R., Parbhakar-Fox, G., Forbes, E. 2023. Effect of pyrite textures and composition on flotation performance: A review. Minerals Engineering, vol. 201, 108234. https://doi.org/10.1016/j.mineng.2023.108234

Kennedy, C.B., Day. S.J., Anglin, C.D. 2016. Geochemistry of Tailings from the Mount Polley Mine, British Columbia. Proceedings Tailings and Mine Waste, p. 857-868.

Kim, Y., Lee, I., Oyungerel, S., Jargal, L. 2013. Petrologic and mineralogical study of Erdenetiin-Ovoo Cu and Mo porphyry deposit, Northern Mongolia. AGU Fall Meeting Abstracts, vol. 2013, pp. V33B-2747.

Kim, Y., Lee, I., Oyungerel, S., Jargal, L., Tsedenbal, Ts. 2014. Mineralogical Study of QSP (Quartz-Sericite-Pyrite) Alteration Zone of Erdenetiin-Ovoo Porphyry Cu-Mo Deposit in Northern Mongolia. Journal of National University of Mongolia, Geological Issues, vol. 13, p. 81-89.

Li, Z., Fu, Y., Yang, C., Yu, W., Liu, L., Qu J., Zhao W. 2018. Mineral liberation analysis on coal components separated using typical comminution methods. Minerals Engineering, vol. 126, p. 74-81. https://doi.org/10.1016/j.mineng.2018.06.028

Licia, S., Putzolu, F., Herrington, R., Dosbaba, M. 2020. Advantages and challenges of integrated automated mineralogy (TIMA X-analyser, TESCAN) during Ni/Co laterite ore characterization: an example from Wingellina deposit (Western Australia). MDSG- 43th Winter Meeting, vol. 129(2), p. 56-85. https://iris.unito.it/handle/2318/1770109

Liu, L., Tan, Q., Liu, L., Cao, J. 2018. Comparison of different comminution flowsheets in terms of minerals liberation and separation properties. Minerals Engineering, vol. 125, p. 26-33. https://doi.org/10.1016/j.mineng.2018.05.023

Liu, T., Song, W., Kynicky, J., Yang, J., Chen, Q., Tang, H. 2022. Automated Quantitative Characterization REE Ore Mineralogy from the Giant Bayan Obo Deposit, Inner Mongolia, China. Minerals, vol. 12(4), p. 426. https://doi.org/10.3390/min12040426

Lotter, N.O., Kowal, D.L., Tuzun, M.A., Whittaker, P.J., Kormos, L. 2003. Sampling and flotation testing of Sudbury Basin drill core for process mineralogy modelling. Minerals Engineering, vol. 16(9), p. 857-864. https://doi.org/10.1016/S0892-6875(03)00207-3

Lu, M., Xie, D.H., Gui, W.H., Wu, L.H., Chen, C.Y., Yang, C.H. 2018. A cascaded recognition method for copper rougher flotation working conditions. Chemical Engineering Science, vol. 175, p. 220-230. https://doi.org/10.1016/j.ces.2017.09.048

Mafra, C., Bouzahzah, H., Stamenov, L., Gaydardzhiev, S. 2020. Insights on the effect of pyrite liberation degree upon the acid mine drainage potential of sulfide flotation tailings. Applied Geochemistry, vol. 123, 104774. https://doi.org/10.1016/j.apgeochem.2020.104774

Martínez-Gómez, V.J., Fuentes-Aceituno, J.C., Pérez-Garibay, R., Lee J. 2016. A phenomenological study of the electro-assisted reductive leaching of chalcopyrite. Hydrometallurgy, vol. 164, p. 54-63. https://doi.org/10.1016/j.hydromet.2016.05.008

McKay, N.A., Wilson, S.W., Lacouture, B. 2007. Ore characterization of the Aqqaluk deposit at red dog. In: Canadian Mineral Processors 39th, Ottawa, Canada, pp. 55-74.

Nyembwe K.J., Fosso-Kankeu, E., Waanders, F., Nyembwe, K.D. 2019. Structural, compositional and mineralogical characterization of carbonatitic copper sulfide: Run of mine, concentrate and tailings. International Journal of Minerals, Metallurgy, and Materials, vol. 26(2), p. 143-151. https://doi.org/10.1007/s12613-019-1718-8

Parapari, P.S., Parian, M., Rosenkranz, J. 2022. Quantitative analysis of ore texture breakage characteristics affected by loading mechanism: Fragmentation and mineral liberation. Minerals Engineering, vol. 182, 107561. https://doi.org/10.1016/j.mineng.2022.107561

Parker, T., Shi, F., Evans, C., Powell. M. 2015. The effects of electrical comminution on the mineral liberation and surface chemistry of a porphyry copper ore. Minerals Engineering, vol. 82, p. 101-106. https://doi.org/10.1016/j.mineng.2015.03.019

Pazhoohan, J., Beiki, H., Esfandyari, M. 2019. Experimental investigation and adaptive neural fuzzy inference system prediction of copper recovery from flotation tailings by acid leaching in a batch agitated tank. International Journal of Minerals, Metallurgy, and Materials, vol. 26(5), p. 538-546. https://doi.org/10.1007/s12613-019-1762-4

Pirrie, D., Butcher, A.R., Power, M.R., Gottlieb, P., Miller, G.L. 2004. Rapid quantitative mineral and phase analysis using automated scanning electron microscopy (QemSCAN); potential applications in forensic geoscience. Geological Society, London, Special Publications, vol. 232(1), p. 123-136. https://doi.org/10.1144/GSL.SP.2004.232.01.12

Qin, S., Dou, S., Ma, S., Zhang, Z., Hu, Y., Li, Y., Liu, P., Lin, F., Zhao, H. 2024. Enhanced recovery of low-grade copper ore and associated precious metals from iron tailings: A case study in China. Colloids and Surfaces A: Physicochemical and Engineering Aspects, vol. 699, 134656. https://doi.org/10.1016/j.colsurfa.2024.134656

Rifai, K., Constantin, M., Yilmaz, A., Özcan, L.Ç., Doucet, F.R., Azami, N. 2022. Quantification of Lithium and Mineralogical Mapping in Crushed Ore Samples Using Laser Induced Breakdown Spectroscopy. Minerals, vol. 12(2), p. 253. https://doi.org/10.3390/min12020253

Rincon, J., Gaydardzhiev, S., Stamenov, L. 2019. Investigation on the flotation recovery of copper sulphosalts through an integrated mineralogical approach. Minerals Engineering, vol. 130, p. 36-47. https://doi.org/10.1016/j.mineng.2018.10.006

Sarantsatsral, N., Ganguli, R., Pothina R., Tumen-Ayush, B. 2021. A Case Study of Rock Type Prediction Using Random Forests: Erdenet Copper Mine, Mongolia. Minerals, vol. 11(10), 1059. https://doi.org/10.3390/min11101059

Sracek, O., Mihaljevič, M., Kříbek, B., Majer, V., Veselovský, F. 2010. Geochemistry and mineralogy of Cu and Co in mine tailings at the Copperbelt, Zambia. Journal of African Earth Sciences, vol. 57(1-2), p. 14-30. https://doi.org/10.1016/j.jafrearsci.2009.07.008

Tiu, J., Ghorbani, Y., Jansson, N., Wanhainen, C., Bolin, N-J. 2022. Ore mineral characteristics as rate-limiting factors in sphalerite flotation: Comparison of the mineral chemistry (iron and manganese content), grain size, and liberation. Minerals Engineering, vol. 185, 107705. https://doi.org/10.1016/j.mineng.2022.107705

Tsend-Ayush, Ts. 2015. Isolation and characterization of lost copper and molybdenum marticles in the flotation tailings of Kennecott copper porphyry ores. Unpublished PhD tthesis, The University of Utah, AAT 3746372.

Tungpalan, K., Wightman, E., Manlapig, E. 2015. Relating mineralogical and textural characteristics to flotation behaviour. Minerals Engineering, vol. 82, p. 136-140. https://doi.org/10.1016/j.mineng.2015.02.005

Vallejos, P., Yianatos, J., Vinnett, L., Bergh, L. 2018. Characterization of the industrial flotation process based on size-liberation relationships. Minerals Engineering, vol. 121, p. 189-195. https://doi.org/10.1016/j.mineng.2018.01.019

Ward, I., Merigot, K., McInnes, B.I.A. 2018. Application of Quantitative Mineralogical Analysis in Archaeological Micromorphology: a Case Study from Barrow Is., Western Australia. Journal of Archaeological Method and Theory, vol. 25(1), p. 45-68. https://doi.org/10.1007/s10816-017-9330-6

Whiteman, E., Lotter, N.O., Amos S.R. 2016. Process mineralogy as a predictive tool for flowsheet design to advance the Kamoa project. Mineral Engineering, vol. 96-97, p. 185-193. https://doi.org/10.1016/j.mineng.2016.05.004

Zhang, P., Ou, L., Zeng, L., Zhou, W., Fu, H. 2019. MLA-based sphalerite flotation optimization: Two-stage roughing. Powder Technology, vol. 343, p. 586-594. https://doi.org/10.1016/j.powtec.2018.11.085

Zhang, X., Kou, J., Sun, C., Zhang, R., Su, M., Li, S. 2021. Mineralogical characterization of copper sulfide tailings using automated mineral liberation analysis: A case study of the Chambishi Copper Mine tailings. International Journal of Minerals, Metallurgy and Materials, vol. 28(6), p. 944-955. https://doi.org/10.1007/s12613-020-2093-1

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Batmunkh Tumen-Ayush, Chinzorig Bavuu, Narangerel Adiyasuren, Ganbileg Davaajav, Davaadulam Batbileg, Sondor Ganbat, Tsend-Ayush Tserendagva, Altankhuyag Dorjyunden, Ganzorig Chimed

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any research article in the Mongolian Geoscientist is retained by the author(s).

The authors grant the Mongolian Geoscientist a license to publish the article and identify itself as the original publisher.

Articles in the Mongolian Geoscientist are Open Access articles published under a Creative Commons Attribution 4.0 International License CC BY.

This license permits use, distribution and reproduction in any medium, provided the original work is properly cited.