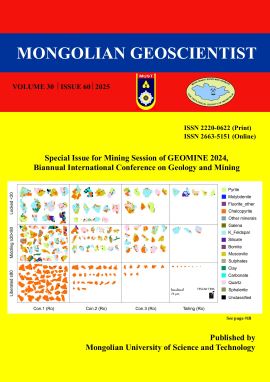

Correlation between ore mineralogical composition at different depths and Bond Work Index for the Erdenetiin Ovoo Cu-Mo porphyry deposit, Mongolia

DOI:

https://doi.org/10.5564/mgs.v30i60.3583Keywords:

ore hardness, estimation model, biotite granodiorite, granodiorite, mineralogyAbstract

The Erdenetiin Ovoo Cu-Mo porphyry deposit in Mongolia is the largest copper mine corporation in the nation. In this study, we investigate the grinding properties of biotite granodiorite and granodiorite rock alteration relative to variations in mine depth, with a specific focus on their correlation with mineral composition. The Bond Work Index experimental tests are applied to the Cu-Mo porphyry ore from the Erdenet Mining Corporation in Mongolia. The samples used in this study were collected representing 10 composites of 5 different depth levels with an interval of ~90 m within the 1175-725 m sampling elevation. The chemical, surface analytical, and mineralogical characterizations of the two types of biotite granodiorite and granodiorite ores are performed using Inductively Coupled Plasma, X-ray fluorescence, and X-ray diffractometer methods. Results of the chemical analysis indicate that the Cu and Mo percentages of both biotite granodiorite and granodiorite consistently decreased with depth profiling. The X-ray diffractometer data of mineral composition are used in setting up the prediction of the Bond Work Index estimation model. An equation-based approach to the Bond Work Index estimation model demonstrates a strong linear correlation (R²=0.895) with the measured Bond Work Index from experimental tests, with the highest Bond Work Index measured at 19.06 kWh/t. Our experimental results indicate that strong correlations were identified between the major mineral phases and the Bond Work Index values through the integration of ore hardness and mineralogical data.

Downloads

490

References

Adler, J., Parmryd, I. 2010. Quantifying colocalization by correlation: The Pearson correlation coefficient is superior to the Mander's overlap coefficient. Cytometry Part A, vol. 77A(8), p. 733-742. https://doi.org/10.1002/cyto.a.20896

Ahmadi, R., Shahsavari, S. 2009. Procedure for determination of ball Bond work index in the commercial operations. Minerals Engineering, vol. 22(1), p. 104-106. https://doi.org/10.1016/j.mineng.2008.04.008

Al-Tigani, M.M.H, Abdueldaem, A.A., Awdekarim, A., Seifelnasr, A.A.S. 2020. Characterization and Bond Work Index Determination of Low Grade Sudanese iron Ore: a case study. International Journal of Academic Engineering Research8 vol. 4(5), p. 13-19. http://ijeais.org/wp-content/uploads/2020/5/IJAER200503.pdf

Bhukte, P.G., Daware, G.T., Masurkar, S.P., Panchal, M.S., Chaddha, M.J. 2023. Effect of Geological, Mineralogical Characteristics on Grindability of Bauxite: A Case Study of Indian Lateritic Bauxite Deposits. Journal of the Geological Society of India, vol. 99(1), p. 55-60. https://doi.org/10.1007/s12594-023-2266-4

Bradshaw, D. 2014. The role of 'process mineralogy' in improving the process performance of complex sulphide ores. 20-24 October, IMPC XXVII, Santiago, Chile, p. 24

Dejidmaa G., Kazuki, N. 1998. Previous studies on the Erdenetiin Ovoo porphyry Cu-Mo deposit, Mongolia. Bulletin of the Geological Survey of Japan, vol. 49(6), p. 299-308. https://www.gsj.jp/data/bull-gsj/49-06_07.pdf

Dominy, S.C., O'connor, L., Parbhakar-Fox, A., Glass, H.J., Purevgerel, S. 2018. Geometallurgy - A Route to More Resilient Mine Operations. Minerals, vol. 8(12), 560. https://doi.org/10.3390/min8120560

Frenzel, M., Baumgartner, R., Tolosana-Delgado, R. and Gutzmer, J., 2023. Geometallurgy: present and future. Elements, vol. 19(6), pp. 345-351. https://doi.org/10.2138/gselements.19.6.345

García, G.G., Oliva, J., Guasch, E., Anticoi, H., Coello-Velázquez, A.L., Menéndez-Aguado, J.M. 2021. Variability study of bond work index and grindability index on various critical metal ores. Metals, vol, 11(6), 970. https://doi.org/10.3390/met11060970

Gerel, O., Dandar, S., Amar-Amgalan, S., Javkhlanbold, D., Myagamarsuren, Se., Myagmarsuren, Sa., Munkhtsengel, B., Soyolmaa, B. 2005. Geochemistry of granitoids and altered rocks of the Erdenet porphyry copper-molybdenum deposit, Central Mongolia. In Mao J., Bierlein, F.P (Eds) Mineral Deposit Research: Proceedings of the Eighth Biennial SGA Meeting, Beijing, China, 18 - 21 August 2005, p. 1137-1140. https://doi.org/10.1007/3-540-27946-6_290

Haruhisa, M. 2003. Geochemical Characteristics of Granitoids of the Erdenet Porphyry Copper Deposit, Mongolia. Resource Geology, vol. 53(4), p. 311-316. https://doi.org/10.1111/j.1751-3928.2003.tb00180.x

Hunt, J., Kojovic, T., Berry, R. 2013. Estimating comminution indices from ore mineralogy, chemistry and drill core logging. Conference Proceedings The Second AusIMM International Geometallurgy Conference (GeoMet) 2013. p. 173-176.

Kalichini, M., Corin, K.C., O'Connor, C.T., Simukanga, S. 2017. The role of pulp potential and the sulphidization technique in the recovery of sulphide and oxide copper minerals from a complex ore. Journal of the Southern African Institute of Mining and Metallurgy, vol. 117(8), p. 803-810. https://doi.org/10.17159/2411-9717/2017/v117n8a11

Keeney, L., Walters, S., Kojovic, T. 2011. Geometallurgical mapping and modelling of comminution performance at the Cadia East porphyry deposit. In GeoMet 2011-1st AusIMM International Geometallurgy Conference, p. 73-83.

Kingman, S.W., Jackson, K., Bradshaw, S.M., Rowson, N.A., Greenwood, R. 2004. An investigation into the influence of microwave treatment on mineral ore comminution. Powder Technology, vol. 146(3), p. 176-184. https://doi.org/10.1016/j.powtec.2004.08.006

Lessard, J., Sweetser, W., Bartram, K., Figueroa, J., McHugh, L. 2016. Bridging the gap: Understanding the economic impact of ore sorting on a mineral processing circuit. Minerals Engineering, vol. 91, p. 92-99. https://doi.org/10.1016/j.mineng.2015.08.019

Magdalinovic, N. 1989. A procedure for Rapid Determination of the Bond work index. International Journal of Mineral Processing, vol. 27(1-2), p. 125-132. https://doi.org/10.1016/0301-7516(89)90010-0

Nghipulile, T., Moongo, T.E., Dzinomwa, G., Nkwanyana, S., Mapani, B., Kurasha, J.T. 2022. Evaluation of the Relationship between the Milling Breakage Parameters and Mineralogical Data: A Case Study of Three Copper Ores from a Multi-Mineralised Deposit. Minerals, vol. 12(10), 1263. https://doi.org/10.3390/min12101263

Paquot, F.X., Ngulube, C. 2015. Development and optimization of mixed sulphide/oxide copper ore treatment at Kansanshi. Journal of South African Institute of Mining and Metallurgy, vol. 115(12), p. 1253-1258. https://doi.org/10.17159/2411-9717/2015/v115n12a15

Parker, T., Shi, F., Evans, C., Powell, M. 2015. The effects of electrical comminution on the mineral liberation and surface chemistry of a porphyry copper ore. Minerals Engineering, vol. 82, p. 101-106. https://doi.org/10.1016/j.mineng.2015.03.019

Sarantsatsral, N., Ganguli, R., Pothina, R., Tumen-Ayush, B. 2021. A case study of rock type prediction using random forests: Erdenet copper mine, Mongolia. Minerals, vol. 11(10). 1059. https://doi.org/10.3390/min11101059

Saxena, R., Rao, D.P., Gautam, A.K., Gautam, M., Gupta, G.P., Kumar, S., Saxena, V., Singh, C.P., Shankar, V., Gautam, Y. 2024. Correlation Coefficient for Physico-chemical Parameters to Assess the Quality of Tannery Effluents at Kanpur. Letters in Applied NanoBioScience, vol. 13(1), 47. https://doi.org/10.33263/LIANBS131.047

Shi, F., Morrison, R., Cervellin, A., Burns, F., Musa, F. 2009. Comparison of energy efficiency between ball mills and stirred mills in coarse grinding. Minerals Engineering, vol. 22(7-8), p. 673-680. https://doi.org/10.1016/j.mineng.2008.12.002

Solomon, N., Becker, M., Mainza, A., Petersen, J., Franzidis, J.P. 2011. Understanding the influence of HPGR on PGM flotation behavior using mineralogy. In Proceedings of the Minerals Engineering, vol. 24(12), p. 1370-1377. https://doi.org/10.1016/j.mineng.2011.07.015

Todorovic, D., Trumic, M., Andric, L., Milosevic, V., Trumic, M. 2017. A quick method for bond work index approximate value determination. Physicochemical Problems of Mineral Processing, vol. 53(1), p. 321-332.

Varianemil, D., Kojovic T., Hakim D., Dilaga R., Condori P. 2023. Ore Hardness Mapping of Batu Hijau Ore Deposit Using the Hardness Index Tester. Proceedings of the SAG Conference, 2023 Vancouver.

Whiteman, E., Lotter, N.O., Amos, S.R. 2016. Process mineralogy as a predictive tool for flowsheet design to advance the Kamoa project. Minerals Engineering, vol. 96-97, p. 185-193. https://doi.org/10.1016/j.mineng.2016.05.004

Zhou, H., Liu, G., Zhang, L., Zhou, C. 2021. Mineralogical and morphological factors affecting the separation of copper and arsenic in flash copper smelting slag flotation beneficiation process. Journal of Hazardous Materials, vol. 401, 123293. https://doi.org/10.1016/j.jhazmat.2020.123293

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Batmunkh Tumen-Ayush, Chinzorig Bavuu, Narangerel Adiyasuren, Davaajargal Darambazar, Ganbileg Davaajav, Khaliun Amartuvshin, Sondor Ganbat, Tsend-Ayush Tserendagva, Altankhuyag Dorjyunden, Ganzorig Chimed

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any research article in the Mongolian Geoscientist is retained by the author(s).

The authors grant the Mongolian Geoscientist a license to publish the article and identify itself as the original publisher.

Articles in the Mongolian Geoscientist are Open Access articles published under a Creative Commons Attribution 4.0 International License CC BY.

This license permits use, distribution and reproduction in any medium, provided the original work is properly cited.